Consulting phone

022-83711102

0311-67163596

022-83711102

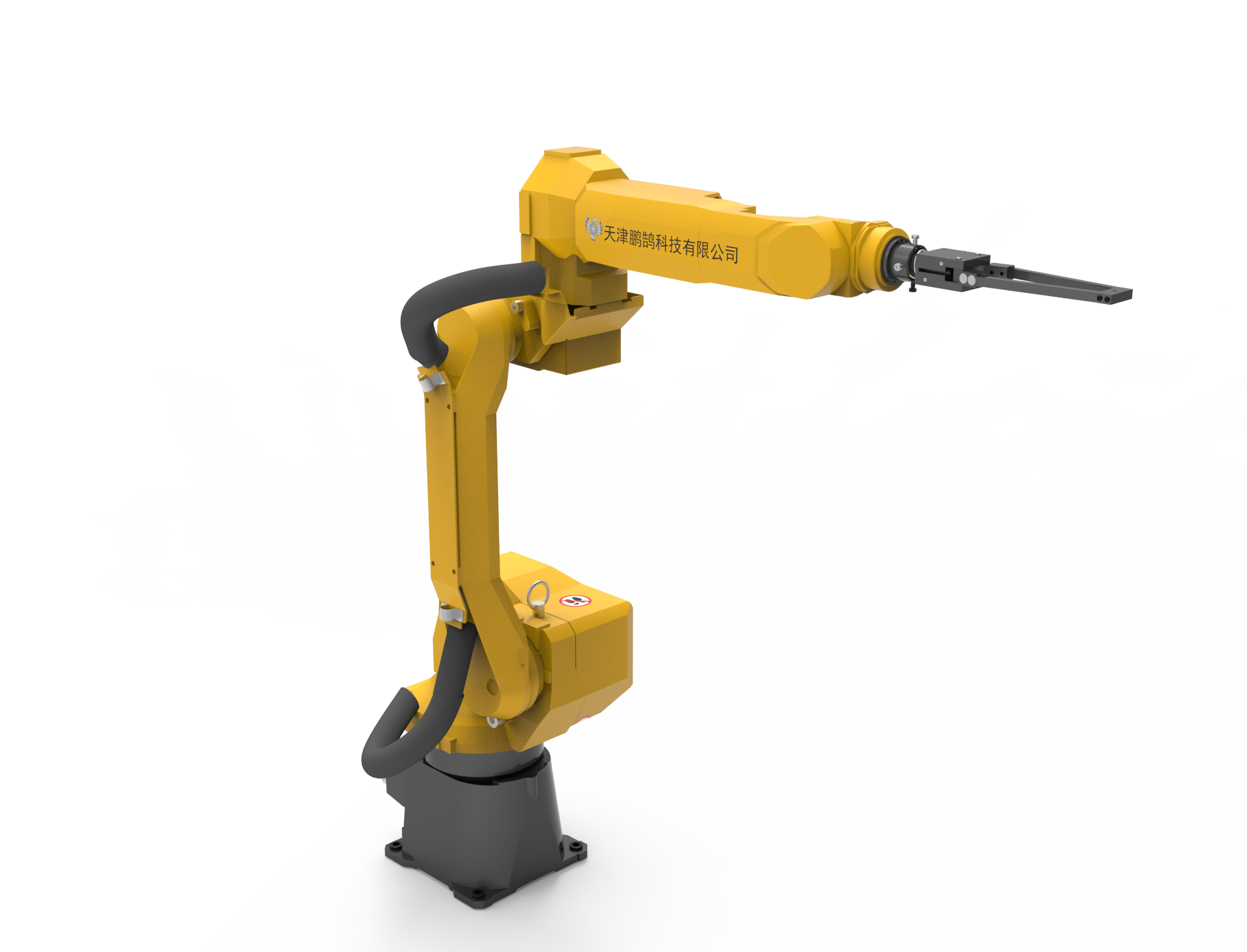

Tianjin Pengyuan Technology Co., Ltd. specializes in creating robot production lines and robotic non-standard customization, such as robot handling, robotic processing technology, robotic assembly, robotic loading and unloading, robotic non-standard equipment, robotic welding and painting and other fields, the implementation of a wealth of project applications. For automotive parts, forging and casting, metal processing and other non-standard automation areas, provide users with automation and robot technical advice, system design, hardware and software environment, robot programming and debugging, robot operation training, maintenance and other solutions!

The development trend of industrial robots is to "high speed, high precision, heavy load, lightweight and intelligent" direction. After continuous improvement, the accuracy of the time accuracy may be close to the repetitive positioning accuracy. Through the progress of material technology, the quality of actuator is reduced, the stiffness is increased, and the average power density of servo motor and actuator is increased. Therefore, industrial robot technology has the following characteristics:

(1) programmable. Further development of production automation is flexible start up. Industrial robots can be reprogrammed according to the needs of their working environment. Therefore, it can play a very good role in the process of flexible manufacturing with balanced and high efficiency in small batches and varieties. It is an important part of flexible manufacturing system.

(2) personification. Industrial robots have human walking, waist rotation, arms, forearms, wrists, claws and other parts of the mechanical structure, in control of the computer. In addition, intelligent industrial robots also have many human-like "biosensors", such as skin-type contact sensors, force sensors, load sensors, visual sensors, acoustic sensors, language functions and so on. Sensors improve the adaptability of industrial robots to the surrounding environment.

(3) versatility. In addition to specially designed industrial robots, general industrial robots have good versatility in performing different tasks. For example, replacing the industrial robot's hand end manipulator (grippers, tools, etc.) can perform different tasks.

Industrial robots have the advantages of high efficiency and reliability, and are widely used in automated production lines. Especially with the advent of the industrial 4.0 era, the world industrial development has entered a new stage characterized by the Internet of Things, mobile Internet, big data, cloud computing and other emerging technologies. Human beings will usher in the fourth industrial revolution marked by highly digitized production, networking, machine self-organization. Robots can not only improve the production efficiency of manufacturing industry and reduce human capital, but also play a very important role in the development of Shenzhen's traditional industries and strategic emerging industries, such as household appliances, communications, electronic information, equipment manufacturing, software, Internet and so on. The strategic significance of the development of the robot industry is no less than each other. The strategic emerging industries and future industries in the region. China has accumulated an important foundation in the research and development of industrial robots: a variety of industrial robots, such as arc welding, spot welding, spraying, handling and so on, have been developed for automotive, aviation and logistics industries, and a great deal of experience has been accumulated in the aspects of mechanism design, drive and control, manufacturing, system integration and engineering application of industrial robots. National "high-grade CNC machine tools and basic manufacturing equipment" major special projects set up "welding robots, spraying robots, handling robots" and other research directions, to further support the development and industrialization of industrial robots.

022-83711102

0311-67163596

Contact usCONTACT US

022-83711102 / 0311-67163596

fax: 022-83711102

Tianjin City

phkj2008@hotmail.com

Pay attention to us

© 版权所有 2017 sjzdydz.com All Rights Reserved 津ICP备17009726号

Technical support:Emperor Yi planning

© 版权所有 2017 sjzdydz.com All Rights Reserved

津ICP备17009726号 技术支持:帝易企划