Consulting phone

022-83711102

0311-67163596

022-83711102

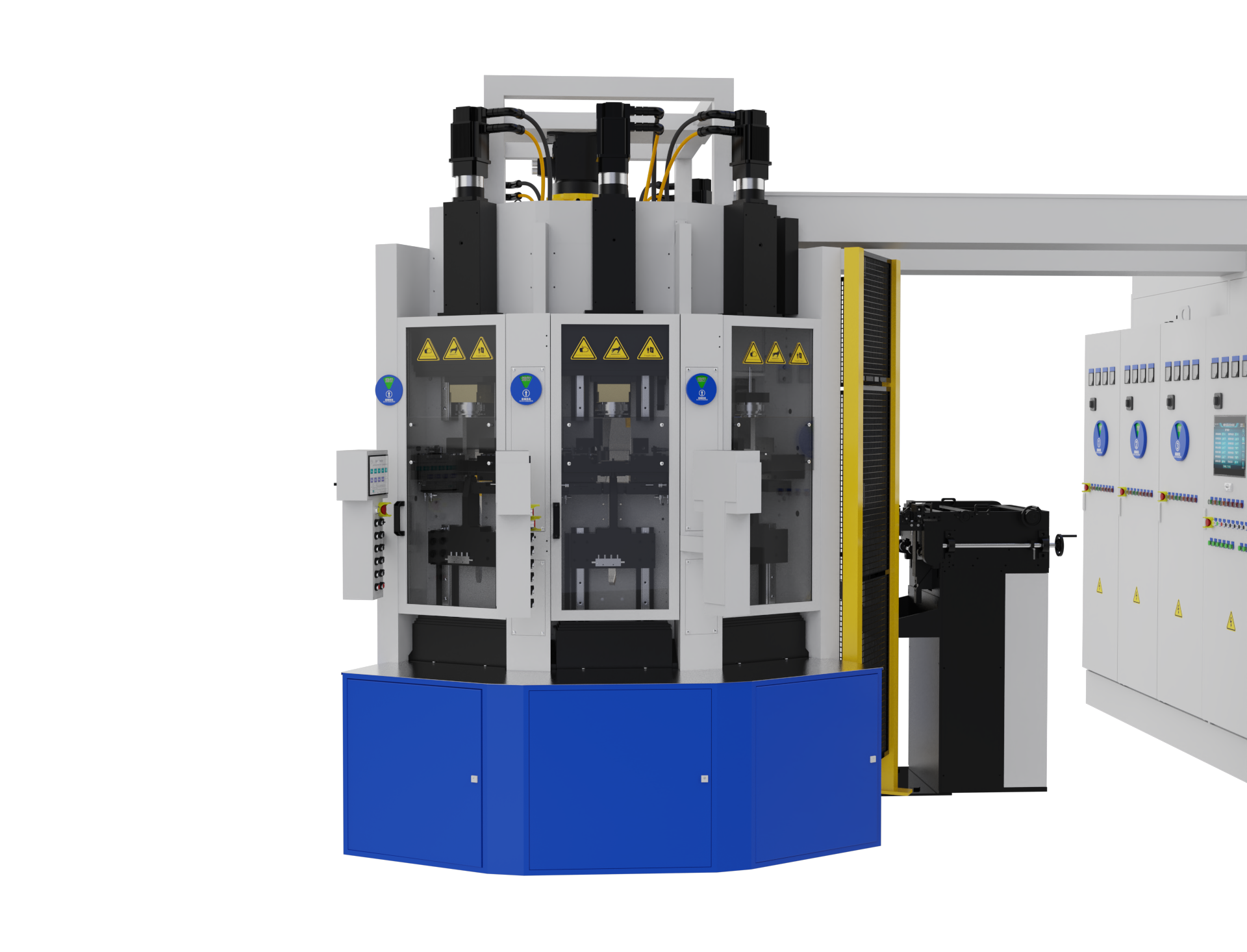

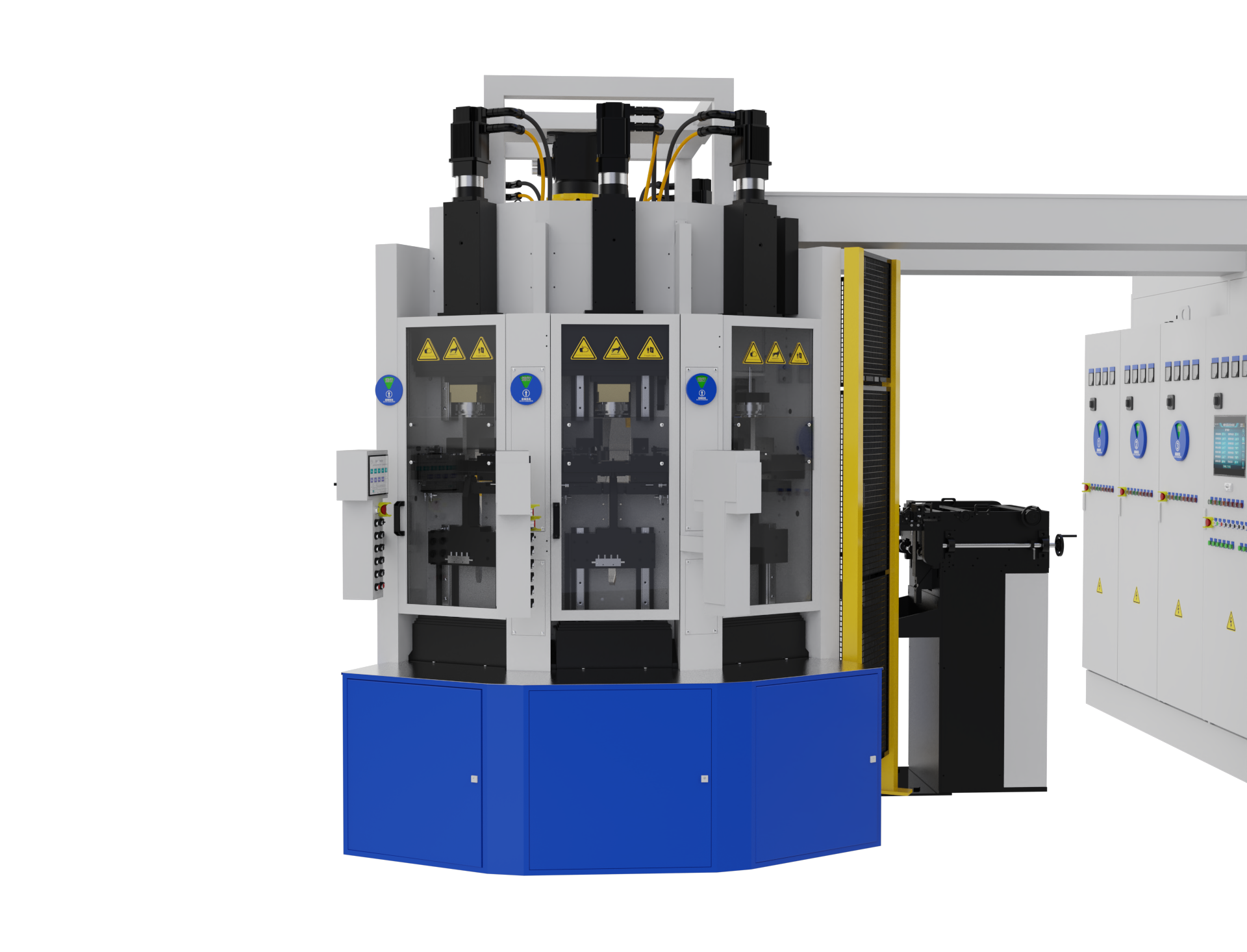

Mechanical part of 1 electric upsetting machine

1.1 body and attachments

The body is made up of 5 parts, namely, the front panel, the upper and lower supporting boards, the rack and the cover plate. The body is equipped for heating transformers and two conductors.

1.2 safety protection device

Safety protection device is composed of two transparent protective door, door stopper and fan induction switch, when the safety door is open the electric upsetting machine will immediately stop working to protect the personal safety

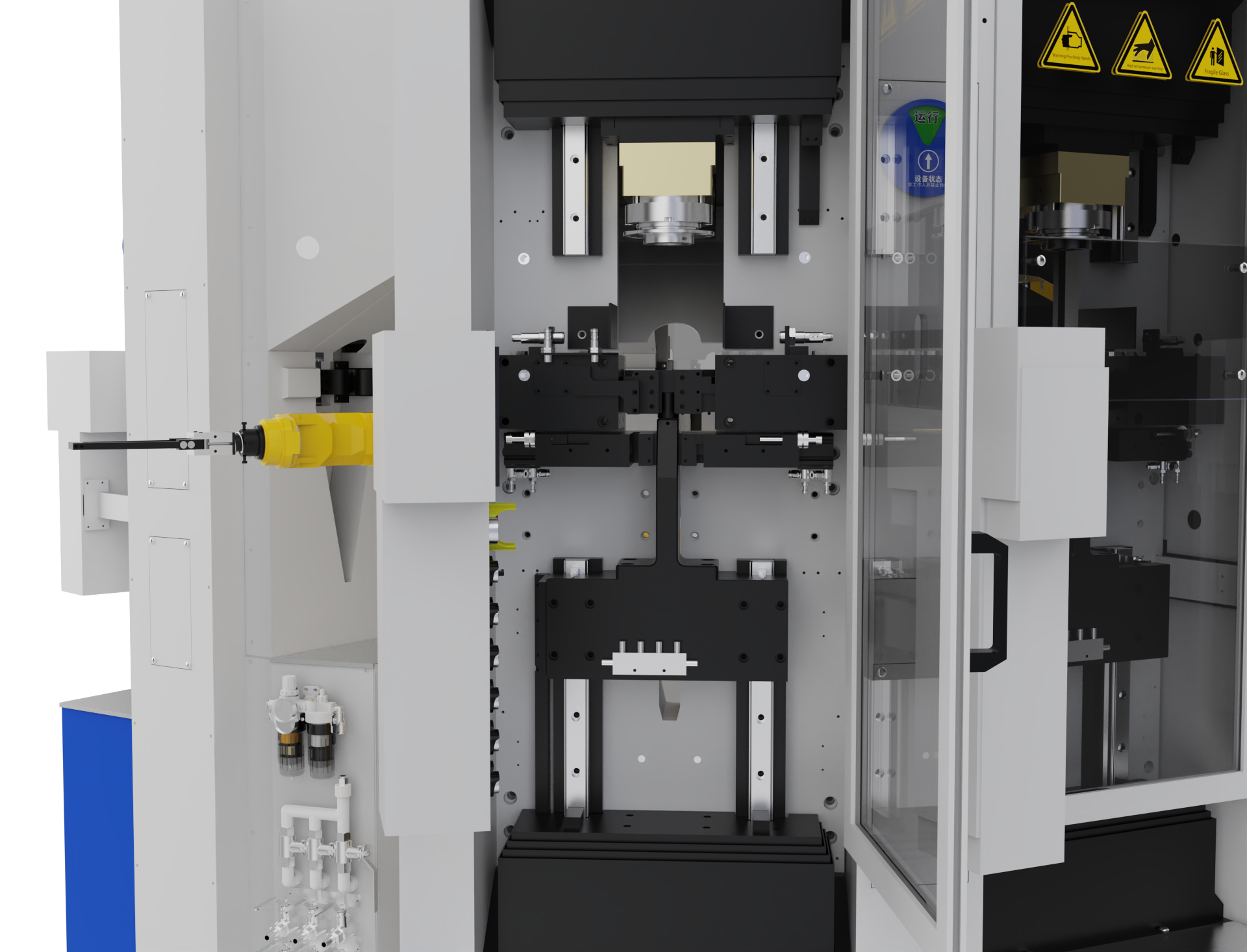

1.3 clamp and automatic middle device

Clamp and automatic centering device is composed of a pair of pliers, a pair of jaw clamp, a tension cylinder, a proportional valve start, tension cylinder while pulling about two clamp clamping workpiece movement.

1.4 anvil back and back device

The anvil return device is composed of a servomotor, a precision planetary reducer, a set of ball screws, a sliding slide block and a set of anvil head pulling devices. The servo motor power is driven by the planetary reducer to rotate the ball screw so that the slider moves up and down.

1.5 hydraulic forging device

The hydraulic upsetting device is composed of a set of independent hydraulic stations, a uniform heavy oil cylinder and a movable slide block. The independent hydraulic station directly drives the heavy oil cylinder, and the oil cylinder drives the movable slide block to move up and down.

1.6 bending device for workpiece

The workpiece anti bending device is composed of two adjustable cylinders and a pair of clamps. The two cylinders directly drive two clamps to the right position to prevent the valve from bending.

1.7 cooling water system

The cooling water system is composed of three waterways, first through the way of cooling water into the anvil electrode after heating transformer flows to the effluent water separator separator, the other two were on both sides of the clamp system, all stainless steel parts (rust plug)

1.8 pneumatic device and piping system:

This equipment is equipped with proportional pressure valves, solenoid valves, filters and piping systems required for electric upsetting. The pressure of the gas source should not be less than 4.5kgf/cm.

2 electrical parts

2.1 electric control system

The electrical control system circuit diagram (see photo), mainly includes: the programmable controller and the output amplifier isolation plate, proportional valve, proportional amplifier board, heating controller, thyristor, heating transformer and some protection components. The electrical control cabinet is installed for maintenance and maintenance independently.

2.2 electric upsetting and heating system

The electric upsetting heating system is located in the body of the electric upsetting machine, which is composed of a heating transformer, an output copper connection, an upper electrode copper plate and a clamp copper electrode. The upper electrode and the clamp electrode are respectively connected with two electrodes of the transformer, and the workpiece is heated by a large current in two electrodes.

2.3 monitoring system

The monitoring system of the electric upsetting machine by the cooling water flow rate monitoring, anvils electrode temperature real-time monitoring, real-time monitoring of hydraulic oil, workpiece temperature pressure real-time monitoring and real-time monitoring system. The omnidirectional monitoring method keeps the electric upsetting machine running in normal working condition to prevent the machine tool from causing illness and reduce the reject rate.

2.4 button box

The button box is made up of a button and a control panel. The button is convenient operator of machine debugging and test running, the control panel can view the current operation of the machine such as the current workpiece temperature, anvil temperature, hydraulic oil temperature, cooling water flow rate, fault code and processing parameters.

022-83711102

0311-67163596

Contact usCONTACT US

022-83711102 / 0311-67163596

fax: 022-83711102

Tianjin City

phkj2008@hotmail.com

Pay attention to us

© 版权所有 2017 sjzdydz.com All Rights Reserved 津ICP备17009726号

Technical support:Emperor Yi planning

© 版权所有 2017 sjzdydz.com All Rights Reserved

津ICP备17009726号 技术支持:帝易企划