Consulting phone

022-83711102

0311-67163596

022-83711102

1. the basic action flow is as follows:

The feeding box selects the qualified rod from the hopper. The feeding robot sends the rod into the electric upsetting machine. The electric upsetting machine begins to upsetting. After the electrical upsetting is completed, the robot will take out the material and put it in the press to make the forging and forming, and finally get the valve blank. The master control system controls these movements in a coordinated and orderly manner, and continues to move back and forth.

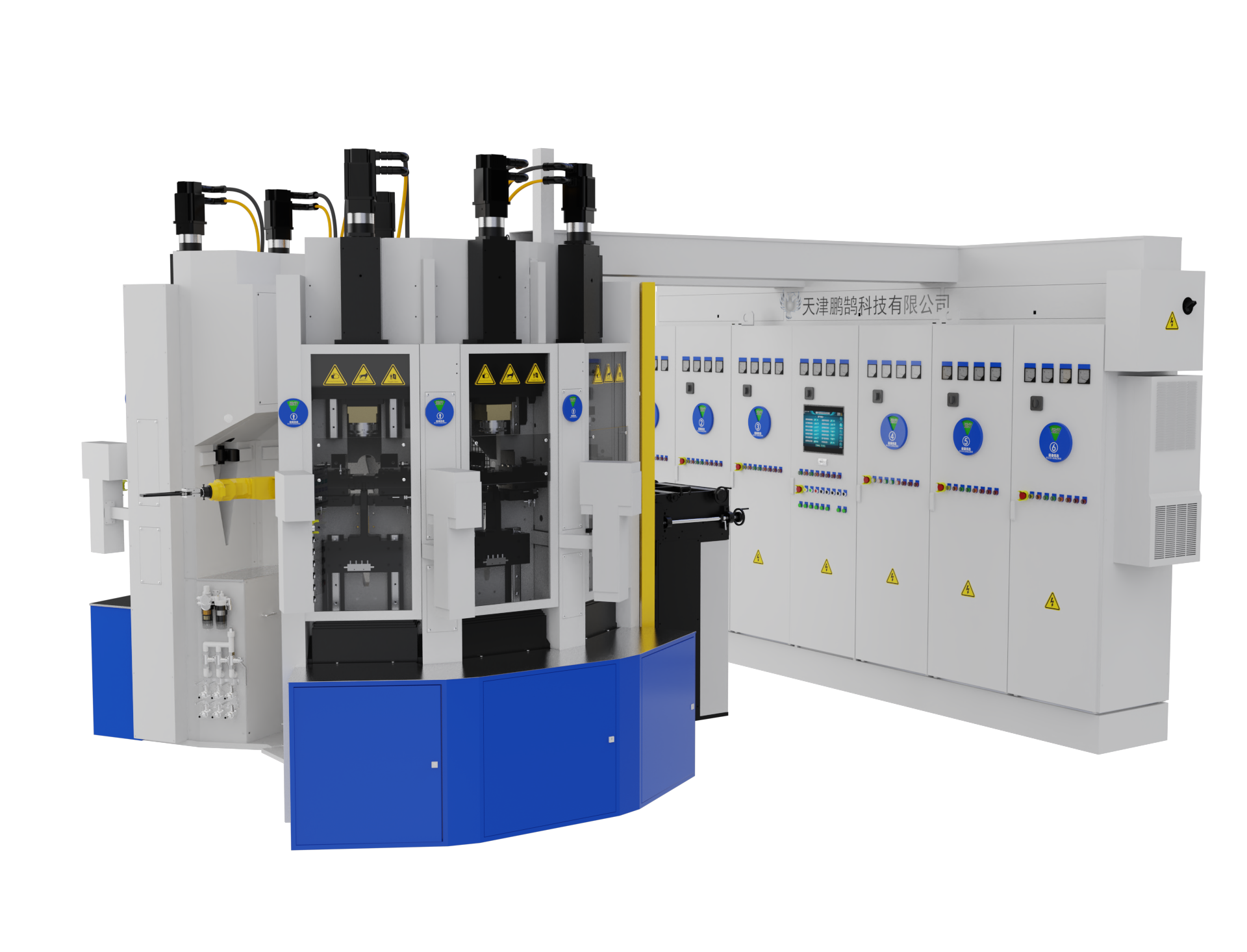

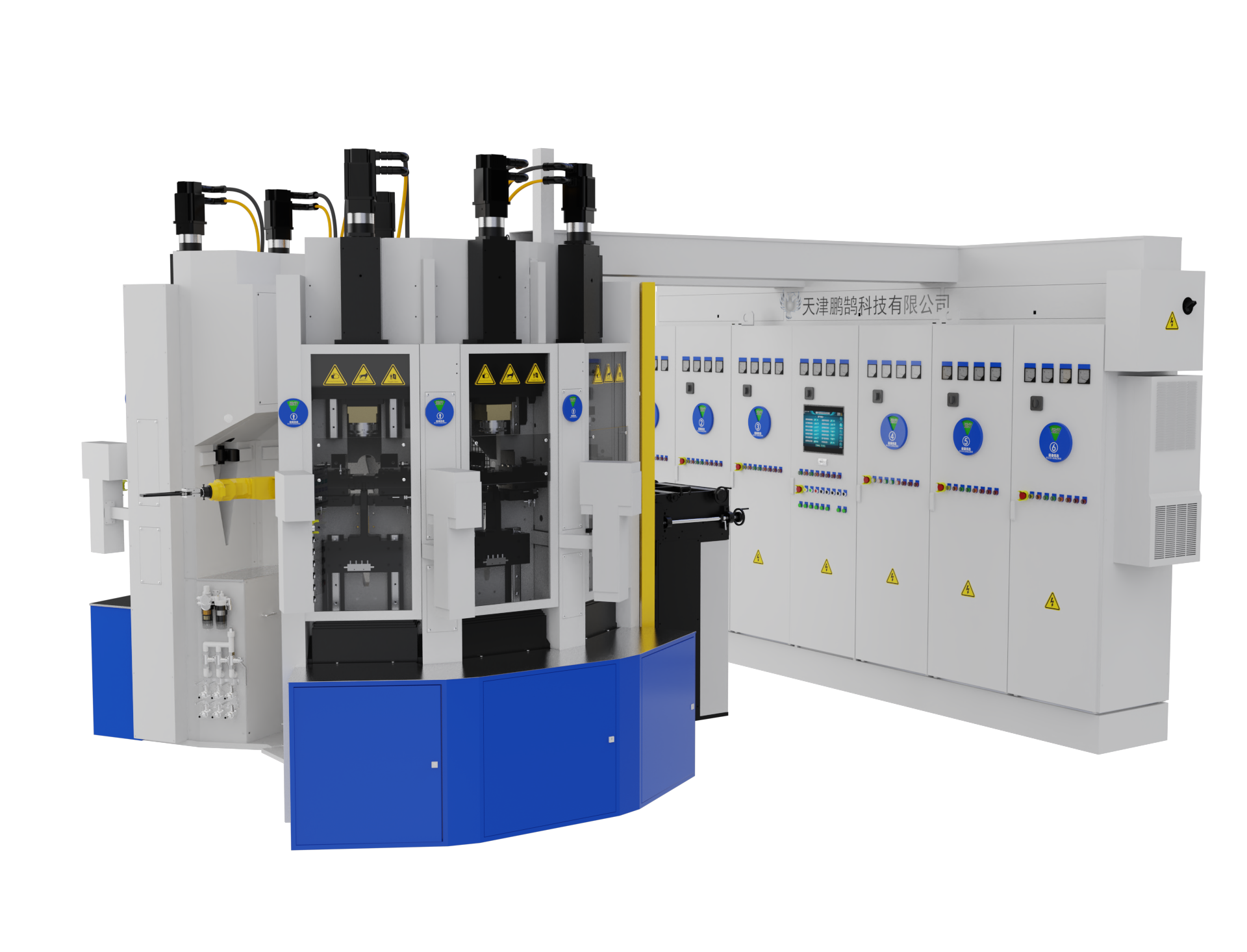

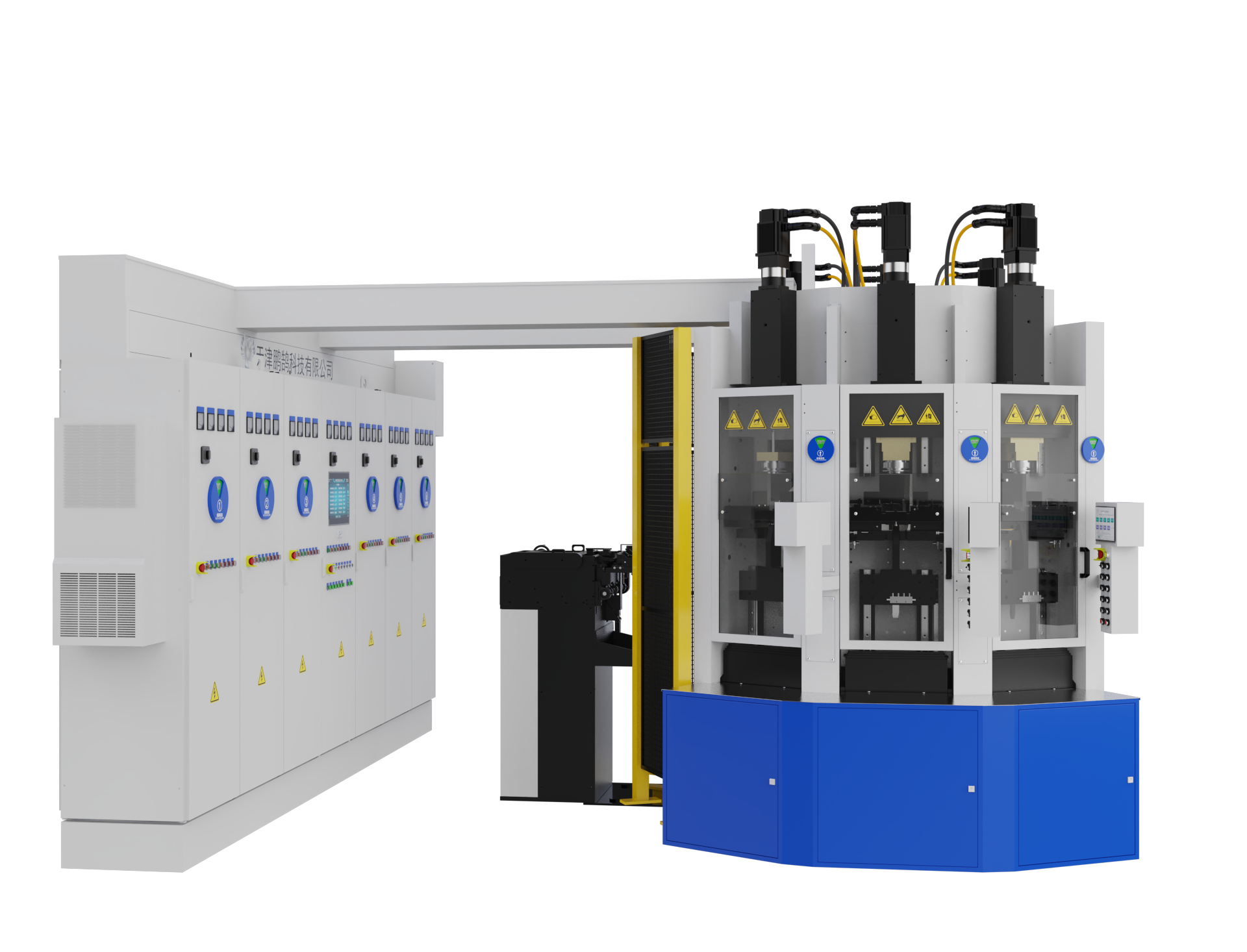

2. production line layout:

Six electric upsetting machines are arranged into two sectors, left and right, left and right, three on the left, three on the right, and a robot in the center of the fan. The robot is hoisted for electrical upsetting material, and the box is divided into the gap between the two sectors. In this way, six sets of electric upsetting machines, one press and two sets of loading boxes are distributed on a circle, and a robot is located in the center of the circle.

Electrical upsetting: the clamp pair is in the middle; the anvil head is automatically to zero; the 50KVA two phase transformer, the no-load current <0.2A; has the anti bending device; it has the electric upsetting preheating, the rod heating, the fixed long electric upsetting, the parameter subsection, the servo ball screw back back.

Total control: parameter storage, work piece count, curve process display, high and low temperature alarm, working state display, fault electroplating machine automatic off-line, electric upsetting machine join and remove online.

Material: magnetic separation and chamfering.

3. workpiece material:

1. The shape of the cross section is round, the diameter is 5 ~ 13, and the size tolerance is ISO standard H11.

Surface condition: cold drawn, peeled or polished oil-free bar.

Surface roughness: Ra 2.5

4. End face state: the end surface of the rod must be smooth, smooth and free from oxidation. The end face has a suitable chamfering angle.

Material: applicable to all steel.

4. productivity:

Upsetting speed directly affects the working cycle and production. Upsetting speed is limited by material alloy, bar diameter, bar surface condition, upsetting shape and transformer power adjustment.

Rod diameter: Ds=8.7mm

Full length of rod: L=300mm

Non upsetting length: k=120mm

Auxiliary time: t=2s

Top upsetting length: L-s=300 - 120=180mm

Top forging speed: v=12mm/s

Anvil head speed: v=2mm/s

Cycle time: Top upsetting length / forging speed anvil speed + auxiliary time = 180 / (12-2) + 5=23s

022-83711102

0311-67163596

Contact usCONTACT US

022-83711102 / 0311-67163596

fax: 022-83711102

Tianjin City

phkj2008@hotmail.com

Pay attention to us

© 版权所有 2017 sjzdydz.com All Rights Reserved 津ICP备17009726号

Technical support:Emperor Yi planning

© 版权所有 2017 sjzdydz.com All Rights Reserved

津ICP备17009726号 技术支持:帝易企划