Consulting phone

022-83711102

0311-67163596

022-83711102

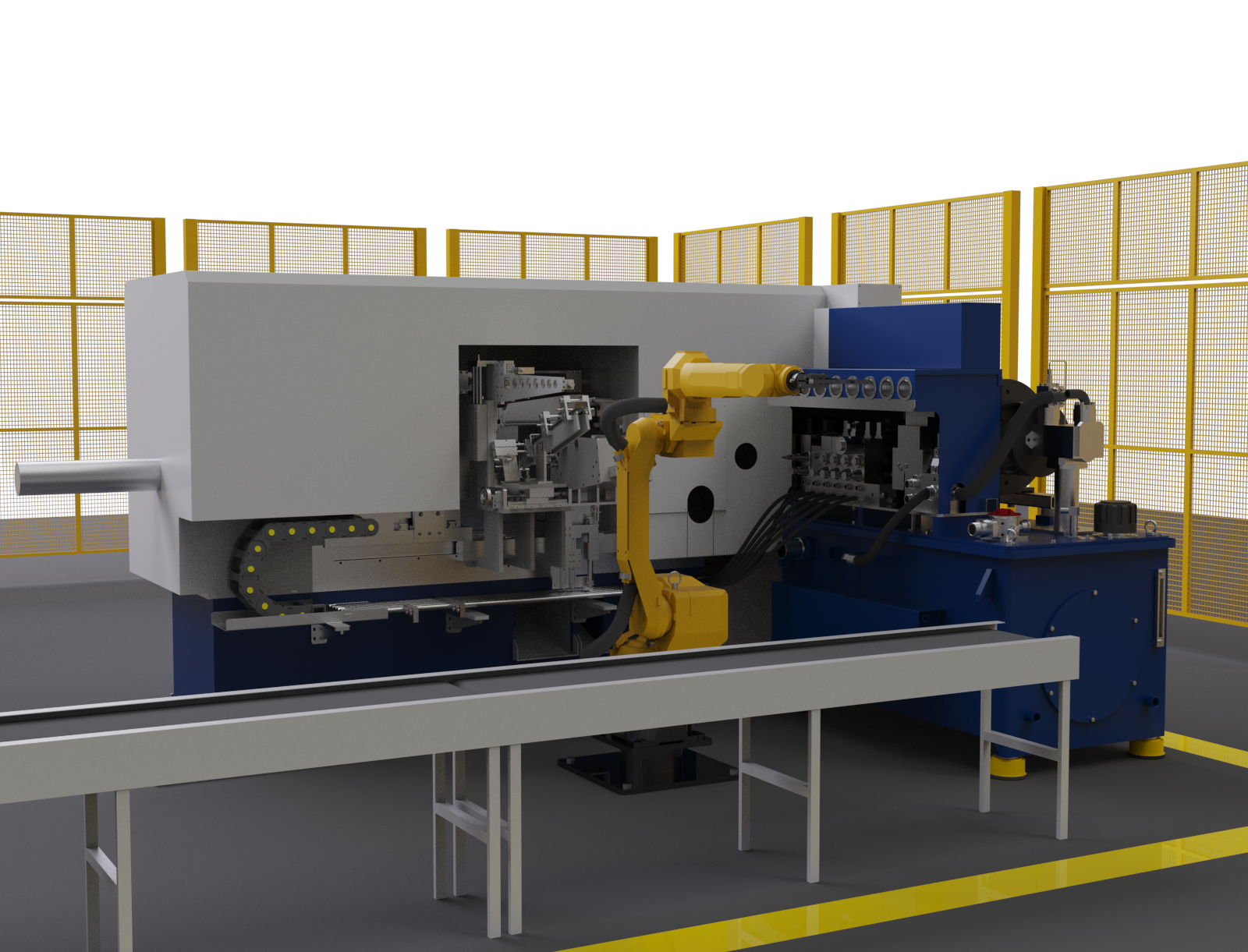

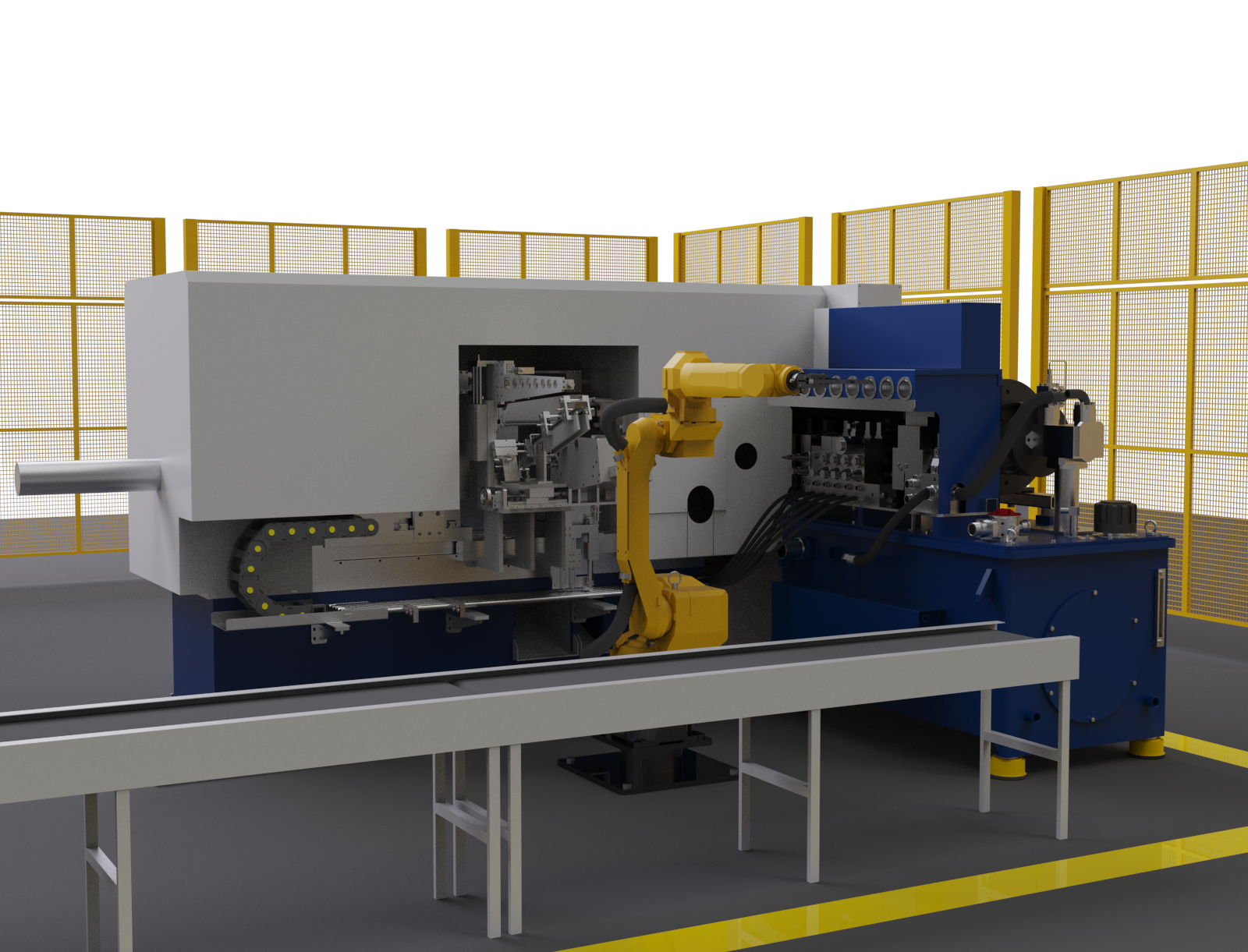

The automation system of non-standard production line mainly consists of the following parts:

(1) automatic transmission line: automatic delivery of the product, and the product tooling board in the assembly work position accurate positioning, assembly completion can make automatic circulation of the tooling board; equipped with motor overload protection, drive chain and transmission chain directly meshing, smooth transmission, reliable operation.

(2) robot system: accurately and quickly complete the assembly of components through a robot in a specific station, which can make the production line achieve a higher degree of automation; the robot can adjust to each other according to certain principles to meet the beat requirement of the process point; and a communication interface with the upper management system is available.

(3) automatic three-dimensional storage feeding system: automatic planning and scheduling and assembly of raw materials, and timely delivery of raw materials to the assembly line, at the same time, the stock materials can be counted and monitored in real time.

(4) full line main control system: the control system based on Fieldbus Profibus DP has not only high real-time performance, but also high reliability.

(5) bar code data acquisition system: making the information of various products standard, accurate, real-time and traceable, the system adopts high grade file server and large capacity storage equipment to quickly collect and manage the production data in the field.

(6) product automated testing system: testing final product performance indicators, transferring unqualified products to repair line.

(7) the production line monitoring / scheduling / management system: using the management layer, monitoring layer and equipment layer three level network for the whole production line comprehensive monitoring, scheduling, management, can accept the workshop production plan, automatic assignment, complete automation production.

022-83711102

0311-67163596

Contact usCONTACT US

022-83711102 / 0311-67163596

fax: 022-83711102

Tianjin City

phkj2008@hotmail.com

Pay attention to us

© 版权所有 2017 sjzdydz.com All Rights Reserved 津ICP备17009726号

Technical support:Emperor Yi planning

© 版权所有 2017 sjzdydz.com All Rights Reserved

津ICP备17009726号 技术支持:帝易企划